In the commercial powder coating and painting industry, efficiency and precision are critical. Wire forms play a key role in keeping production lines running smoothly, allowing parts to move seamlessly through conveyor systems while being coated or painted. At Ace Wire Spring & Form Co., Inc., we design and manufacture durable custom wire forms to meet the unique needs of coating and finishing operations.

Wire forms are essential for:

Hanging and supporting parts of all shapes and sizes during coating applications.

Positioning and maneuvering components through automated conveyor lines.

Ensuring consistent finishes by holding parts securely in place for even paint or powder coverage.

By using the right wire forms, manufacturers avoid production slowdowns, coating defects, and rework—saving both time and costs.

We produce wire forms from high-quality materials, including:

Spring steel – offering strength and resilience under repetitive use.

Stainless steel – ideal for corrosion resistance and long-term durability.

Low carbon steel – providing flexibility for custom shapes and affordability.

Each material is selected to maximize performance in demanding coating environments.

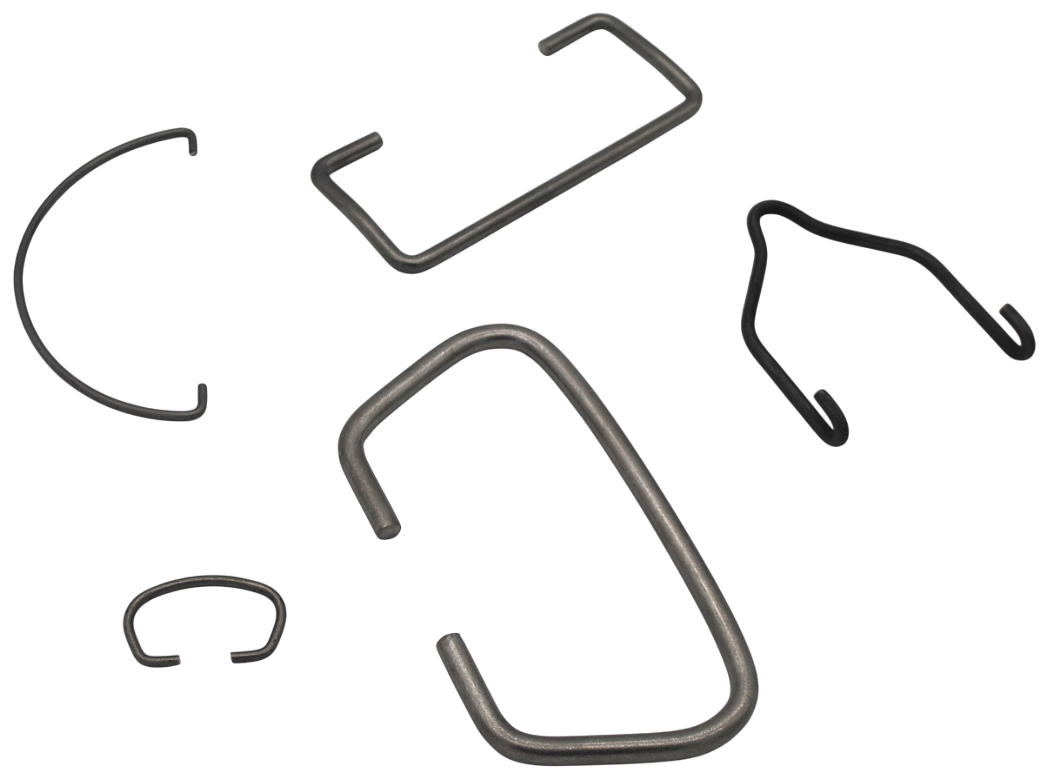

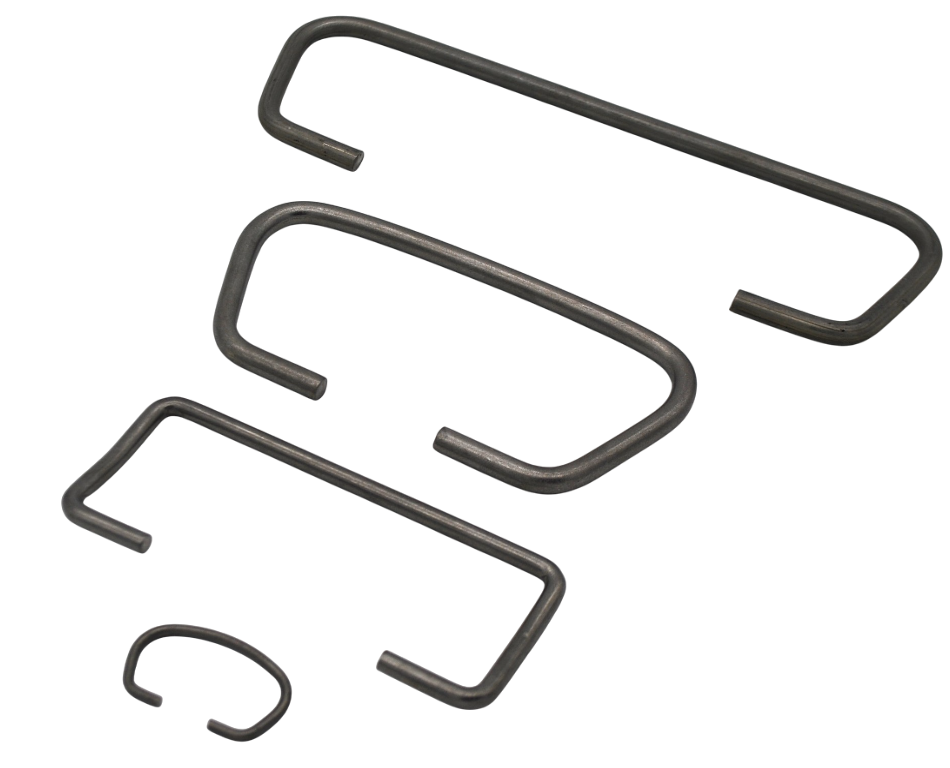

Some of the most common wire forms we supply for powder coating and painting systems include:

Hanging Hooks for Conveyor Belts – Designed to hold parts securely as they move through automated systems.

Custom Hook & Hanger Shapes – S-hooks, V-hooks, C-hooks, square wires, and specialized designs crafted to meet your exact specifications.

These are just a few examples. Our engineering and production teams can design virtually any custom wire form needed to fit your process, from simple hangers to complex multi-part solutions.

With decades of experience in wire forming, we offer more than just manufacturing. Our team provides engineering design assistance, prototyping, and large-scale production tailored to the coating industry. Whether you’re looking for a quick turnaround on prototypes or a blanket order program for ongoing supply, we deliver dependable solutions that keep your finishing lines operating at peak efficiency.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.