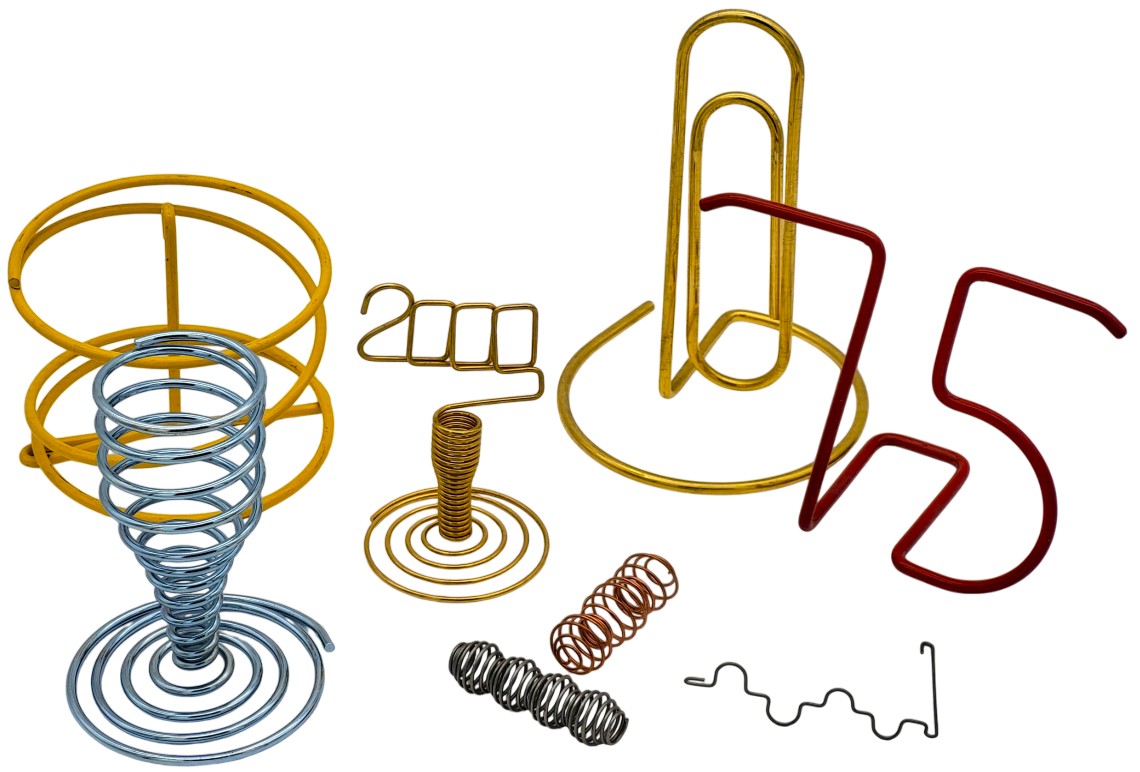

Discover why small-batch custom spring quotes often have higher per-piece pricing than large runs. Learn how Ace Wire Spring’s custom manufacturing process, material sourcing, and industry expertise impact your quote. As a custom Pittsburgh, Pennsylvania spring manufacturer, we support a wide range of industries—from circuit breakers and high voltage electrical switch gear to agriculture, transportation, and medical. Every spring we produce is made-to-order, tailored to your exact requirements, using materials carefully selected for your application.

Unlike mass-production suppliers, Ace Wire Spring operates as a custom job shop. We do not carry off-the-shelf inventory. Every project begins with detailed engineering analysis and tailored production. The process includes:

These steps are essential for every order—whether you need 10 or 10,000 springs. The difference? In a large run, those upfront costs are spread over more parts, significantly reducing the per-unit cost.

Even for low-volume jobs, we must source the exact spring wire material your application requires—carbon steel, stainless steel, or specialty alloys. Most wire suppliers have minimum order quantities, meaning we may have to purchase far more material than the job requires, which increases your quote.

Our CNC spring coiling and forming machines require precise setup and programming. This includes:

Whether we’re making 10 parts or 10,000, the time investment is similar. For low-quantity orders, setup time becomes a major factor in your per-piece price.

For customers developing new products or testing unique applications, we offer prototyping services backed by full engineering and design support. Our experienced engineering team will review your drawings, physical samples, and specifications using spring design software to validate tolerances, loads, and functionality.

When needed, we’ll offer recommendations to refine your design to ensure manufacturability and performance. Other spring suppliers may offer standard parts with little design input—but at Ace, we do the legwork to get your custom solution off the ground.

We can ship prototypes or samples, gather your feedback, and iterate until the part performs exactly as needed. That hands-on collaboration is what sets us apart.

Ace Wire Spring supports industries where small quantities of precision-engineered springs are often needed:

Our team has the experience to support both prototype and production runs with responsive customer service, quick lead times, and precision craftsmanship.

When requesting a low-volume quote from Ace, you’re investing in more than just materials:

We pride ourselves on offering U.S.-made custom springs that perform reliably under the most demanding conditions.

As a leading Pittsburgh spring manufacturer, Ace Wire Spring & Form Co., Inc. has proudly served Western Pennsylvania and the surrounding areas for over 85 years. Located in the heart of Pittsburgh, our facility combines time-tested craftsmanship with advanced CNC spring coiling and wire forming technology to deliver high-quality, made-to-order springs for a wide range of industries.

Whether you’re a local OEM, engineer, or purchasing agent searching for a custom spring supplier in Pittsburgh, we offer the technical expertise and production capabilities to support your small-batch prototypes and large-scale production runs alike. Our team is deeply rooted in the community, committed to American manufacturing, and trusted by companies across the trailer, agriculture, defense, energy, and medical sectors.

At Ace Wire Spring & Form Co., Inc., we provide fast, accurate quotes and design support tailored to your application. Submit a Request for Quote (RFQ) today with as much information as possible—a drawing, sample, photo, or even a stock part number.

Let us show you why leading OEMs, engineers, and purchasing professionals choose Ace for their custom spring needs.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.