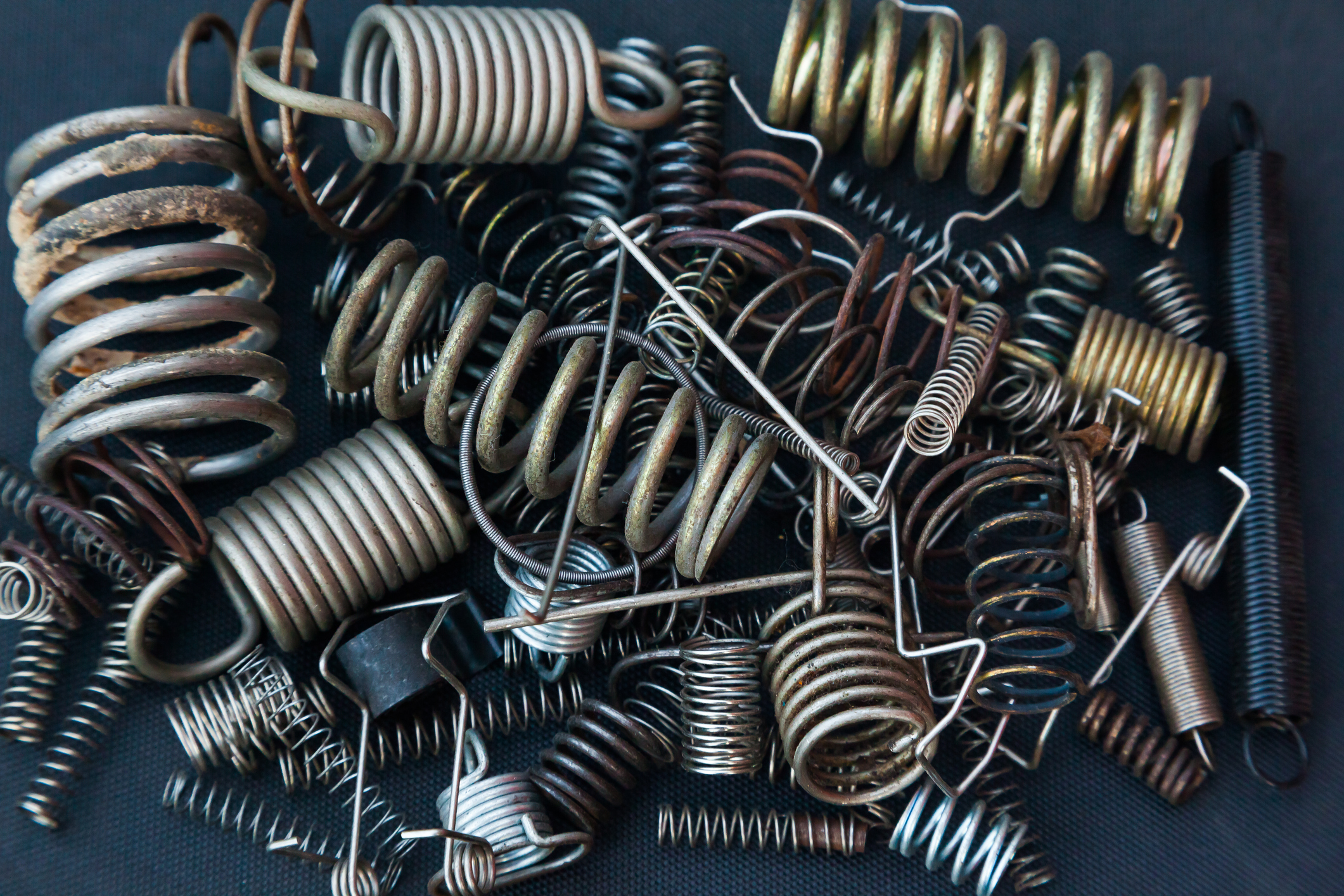

When a spring fails, the entire system can fail with it. Whether you’re designing custom compression springs, torsion springs, extension springs, or custom wire forms, understanding why springs fail—and how to prevent it—is essential for performance, reliability, and cost efficiency. At Ace Wire Spring & Form Co., Inc., we’ve spent over 85 years helping engineers and manufacturers overcome these challenges with precision spring manufacturing and design support.

One of the most common causes of spring failure is improper material selection. Each material has unique characteristics that affect fatigue life, corrosion resistance, and load capacity. For example:

Music wire offers excellent strength but limited corrosion resistance.

Stainless steel wire performs better in moisture and chemical environments.

Inconel, phosphor bronze, and Elgiloy provide enhanced performance for high-temperature or corrosive applications.

Selecting the wrong wire type for your environment leads to early fatigue, rust, or permanent deformation.

Tip: Always consider operating temperature, load requirements, and environmental factors before specifying spring material.

A custom compression spring or torsion spring may look simple, but the internal stresses are complex. Over-compressing or over-twisting a spring beyond its elastic limit can cause permanent set or breakage. This issue is especially common in applications where space is tight or where designers underestimate spring travel.

Tip: Always calculate maximum deflection and solid height. Leave enough clearance to prevent coil bind.

Inaccurate specifications during the design phase can lead to spring failure under load or improper fit during assembly. Springs are precision components, and a small deviation in wire diameter, free length, or pitch can result in significant performance differences.

Tip: Verify tolerances early. Ace Wire Spring offers design assistance and prototyping to help ensure your spring meets performance requirements before production.

Springs used in power generation, medical equipment, or material handling systems often experience thousands—or millions—of cycles. Fatigue failure occurs when the spring’s stress levels exceed its endurance limit over time. This can result in cracking or breakage, especially in high-cycle environments.

Tip: Choose the correct wire type and surface finish, and ensure stress levels are within the fatigue life range for your application.

Without proper heat treatment, a spring’s molecular structure retains residual stress from coiling, making it brittle or unstable under load. Every high-quality custom spring manufacturer must apply controlled stress relief to restore elasticity and improve fatigue resistance.

Tip: Verify your manufacturer performs heat treatment appropriate to the wire material and spring function.

Surface imperfections—such as tool marks, scratches, or corrosion—can act as initiation points for fatigue cracks. Proper finishing, plating, or coating extends spring life, particularly for outdoor or corrosive environments.

Tip: Consider zinc plating, black oxide, or passivation for enhanced corrosion resistance, depending on the wire type and end use.

Even the best design can fail without thorough testing. At Ace Wire Spring, we emphasize rapid prototyping and functional testing to validate spring performance before full-scale production. Skipping this step often leads to field failures and costly redesigns.

Tip: Always test prototypes under actual load and environmental conditions. Partner with a custom spring manufacturer that provides measurable testing data.

Ace Wire Spring & Form Co., Inc. combines decades of hands-on experience with advanced CNC spring coiling and wire forming equipment to ensure every part meets precise design and performance requirements. From custom wire forms to high-precision compression, extension, and torsion springs, our team collaborates with engineers to deliver reliable, long-lasting solutions.

By addressing these common spring design mistakes early—through proper material selection, accurate specifications, and controlled manufacturing—you can dramatically extend the life of your spring and improve the overall performance of your product.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.