If you need a trailer ramp assist spring quoted quickly and correctly, the most important step is providing clear spring specifications. Ramp assist springs are torsion springs that are highly application specific, and even small differences in size, leg configuration, or material choice can change performance, fit, and service life.

This article explains how to specify a trailer ramp assist spring in a way that helps a custom spring manufacturer quote it faster, build it correctly, and deliver consistent performance in real trailer conditions.

Ace Wire Spring and Form Co. supports OEMs and equipment manufacturers with custom trailer springs, prototype springs, and production quantities. If you are replacing a broken ramp spring, improving ramp control, or upgrading durability, these guidelines will help you request a quote with confidence.

A trailer ramp assist spring helps counterbalance the weight of a trailer ramp or door. As the ramp moves, the torsion spring stores energy, then releases that energy to reduce the lifting force required by the operator. When properly specified, a ramp assist spring improves safety, reduces strain, and provides smoother ramp movement during opening and closing.

Ramp assist springs are commonly used on utility trailers, enclosed trailers, landscape trailers, and equipment trailers. They are also frequently exposed to outdoor conditions like rain, road salt, dirt, and temperature swings. That is why correct spring selection matters for both performance and long term reliability.

Many ramp assist spring issues come from incorrect or incomplete information during sourcing. A spring that is slightly too strong may cause the ramp to snap open aggressively or feel unstable. A spring that is too weak may not provide enough assistance, making the ramp heavy and difficult to control. In other cases, the spring may fit physically but fail early due to fatigue, corrosion, or improper stress levels.

Providing accurate spring dimensions and application details helps prevent these issues. It also helps your manufacturer recommend improvements based on experience, such as a better spring material, a more durable finish, or a small geometry change that improves life without affecting installation.

Before measuring the spring, it helps to describe how it works in your ramp system. Trailer ramp assist springs are installed in a way that depends on the hinge arrangement, mounting hardware, and whether the system uses one spring or a matched pair. Even if the spring looks simple, the installation constraints can make the design very specific.

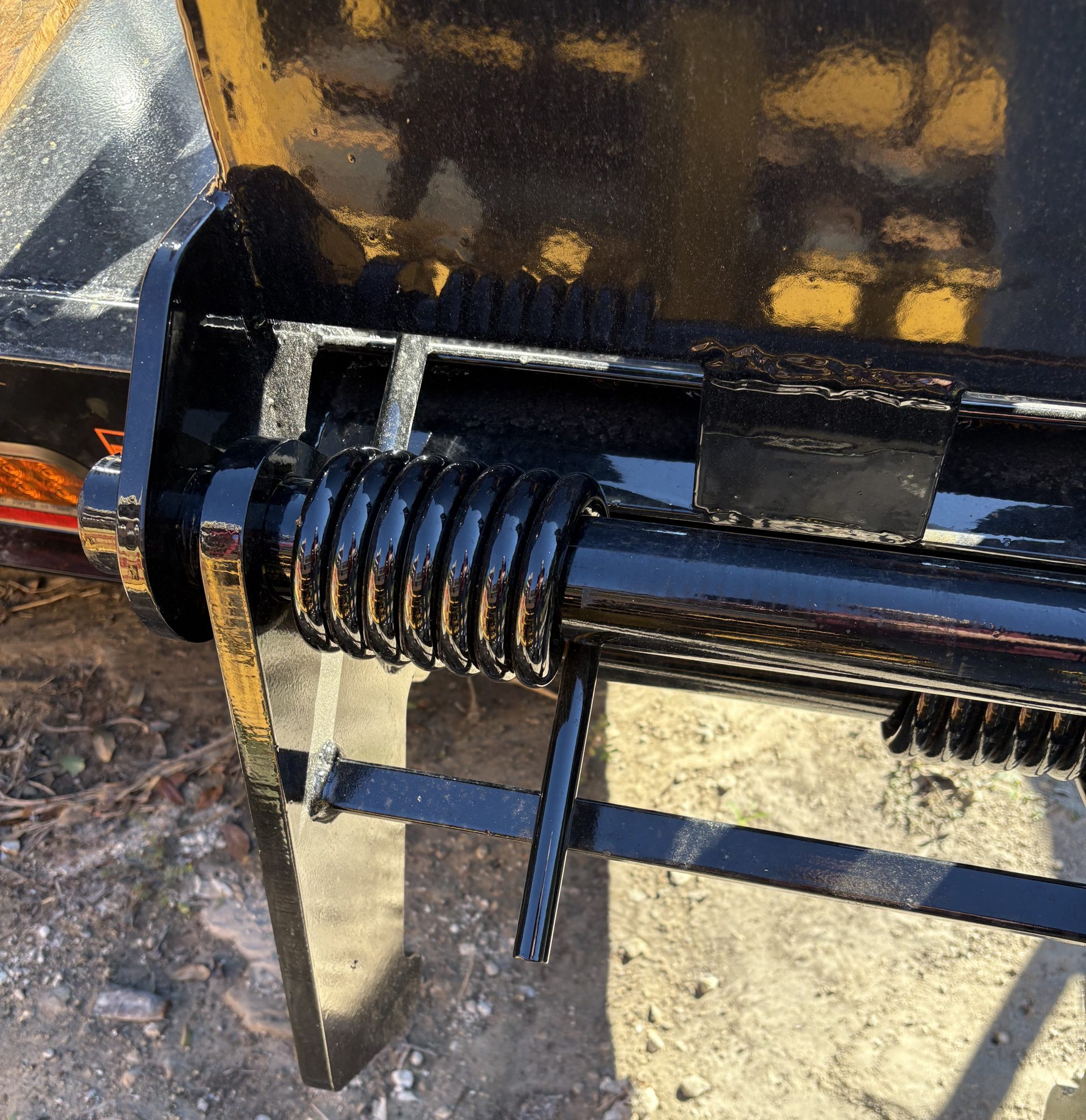

If you are requesting a quote, include a short description of the trailer type and ramp style, and mention anything you know about ramp weight, ramp width, or the motion range. If you have photos of the spring installed and photos of the mounting points, those images can save time and reduce back and forth questions during quoting.

Most trailer ramp assist springs can be quoted accurately when the key coil dimensions and leg details are clearly provided. The wire diameter is one of the most important measurements because it strongly affects torque output, spring stress, and fatigue life. This is best measured with calipers, since guessing wire size often leads to incorrect quotes and incorrect performance.

The spring diameter is also critical because it determines how the spring fits around a shaft or inside a housing. Most customers provide outside diameter because it is easier to measure, but inside diameter can also be used if that is what you have available. Along with diameter, the length of the spring body matters because it affects fit, torque distribution, and how the spring interfaces with brackets or spacers.

If you can provide coil count, that can be helpful as well, especially if the spring has unusual spacing or if the coil body length is difficult to measure due to leg bends. In many cases, the spring body length and coil count together help confirm the spring geometry and avoid misinterpretation.

For trailer ramp assist springs, leg configuration is frequently the biggest reason two springs are not interchangeable. Two springs can share the same wire size and coil diameter, yet behave completely differently because the legs are formed differently or oriented in a different direction.

When you request a quote, include leg length on both ends and describe how the legs are bent. If possible, explain the leg angles or provide a photo showing the leg orientation relative to the spring body. If the spring has special forming features such as a hook, a tight bend, or a unique offset, those details should be captured clearly.

Wind direction is another factor that affects installation and function. If you are not sure whether the spring is left hand wound or right hand wound, a manufacturer can often determine it from photos or a sample spring. Providing multiple angles is usually enough to confirm it quickly.

Material choice affects how long a trailer ramp assist spring lasts and how consistently it performs over time. Many trailer applications use high carbon spring steel, but certain operating conditions may benefit from materials with improved fatigue performance or different corrosion resistance characteristics.

If the ramp assist spring is cycling frequently, carrying heavy loads, or failing early from fatigue, chrome silicon may be worth considering depending on the design requirements. If corrosion is the main issue, stainless steel can be an option for certain environments, although it may not always be the best choice for every ramp assist spring due to performance and cost tradeoffs.

The best approach is to share your environment and failure history. If the current spring is rusting, pitting, cracking, or losing force, those symptoms help guide better material selection and longer life.

Trailer ramp assist springs often fail early due to corrosion, especially in wet environments or regions where road salt is common. Corrosion can create surface damage that accelerates fatigue cracking and shortens spring life.

A protective finish or coating can help improve durability. Zinc plating is common for corrosion protection, and other finishes may be appropriate depending on your needs. If you have a finish requirement from your engineering team or customer specification, include it in your request. If you are not sure, mention the environment and allow your manufacturer to recommend an option based on experience.

Not every customer has a torque requirement available, and that is normal. If you do have torque targets, those are useful for dialing in the correct spring output. If you do not, you can still provide performance goals that describe what you want the ramp to feel like.

For example, you may be trying to reduce lift effort, prevent the ramp from slamming down, or improve controlled motion through the full opening range. You may also be replacing a spring that feels too aggressive or too weak. These details help a manufacturer understand what you are trying to achieve and support better recommendations.

If you are developing a new trailer ramp design, it is also helpful to describe the intended user experience. A spring that works for one ramp weight and hinge setup may not work for another, even if the spring dimensions look similar.

When you request a custom spring quote, quantity affects both price and lead time. If you need prototype springs first, mention that up front. If you are planning for production quantities, provide an estimated annual usage if possible. This helps your manufacturer plan material sourcing, tooling, and production scheduling more effectively.

Many OEMs start with a small sample quantity for fit and function validation, then move into repeat production. A clear timeline helps avoid delays and keeps your project moving.

The fastest quotes typically come from requests that include accurate measurements and clear visuals. A few well lit photos of the spring installed and removed often eliminate confusion about leg orientation, mounting constraints, and wind direction. If you can include wire diameter, outside diameter, spring body length, and leg lengths, you will usually get a much faster and more accurate response.

If you have an existing spring sample, that can also be a reliable way to confirm the details and reduce risk, especially when the spring has complex leg geometry or must fit into a tight assembly.

If you need a trailer ramp assist spring manufacturer that supports both prototypes and production, Ace Wire Spring and Form Co. can help. We manufacture custom springs and wire forms built to customer specifications, with a focus on consistent performance, repeatability, and responsive quoting support.

If you are replacing a ramp assist spring that keeps failing, improving corrosion resistance, or building a new trailer ramp system, the right specifications make all the difference.

If you need a quote for trailer ramp assist springs, send your spring measurements, photos, and any application details you have available. The more complete the information, the faster we can help you move from quote to prototype to production.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.