Manufacturers across the United States rely on custom springs and wire forms made in the USA to support critical equipment, electrification systems, power generation infrastructure, medical devices, transportation assemblies, and conveyer systems. When performance, consistency, and long term reliability matter, sourcing custom springs and wire forms made in the USA offers major advantages in quality control, lead time stability, engineering collaboration, and supply chain security.

American made custom springs and wire forms help OEMs reduce risk while improving long term production performance. Custom spring and wire form manufacturing in the United States allows OEMs and equipment builders to work closely with experienced manufacturers who understand tight tolerances, complex applications, and high cycle performance demands.

From prototyping to full scale production, domestic manufacturing supports faster iterations, better communication, and repeatable quality across production runs. Ace Wire Spring and Form Co. manufactures custom springs and wire forms made in the USA to customer specifications, supporting a wide range of industries with precision manufacturing, responsive service, and consistent performance.

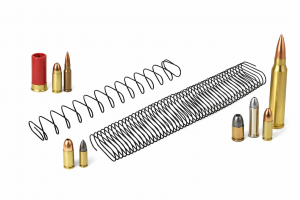

Custom springs and wire forms are essential components across nearly every industrial sector. Power generation and electrical equipment use precision springs for switchgear, breakers, substations, turbines, and control systems where durability and consistent force are critical. Medical device manufacturers depend on small, high tolerance springs and wire forms for surgical tools, diagnostic equipment, and automated systems where repeatability and cleanliness are mandatory. Industrial machinery and automation systems rely on springs for motion control, vibration dampening, indexing mechanisms, and actuator assemblies that operate continuously under demanding conditions. Transportation applications use springs and wire forms for suspension components, braking systems, safety mechanisms, and structural supports that must perform reliably over extended service life. Defense and firearms manufacturing require repeatable, high cycle springs that meet strict performance standards and documentation requirements. Across all of these industries, custom spring solutions made in the USA provide performance and durability that standard off the shelf components often cannot achieve.

In addition to springs, custom wire forms made in the USA support equipment assemblies and structural components across multiple industries. Wire forms are shaped wire parts designed to provide retention, support, positioning, protection, or mechanical linkage within an assembly. USA manufactured wire forms are commonly used in automation equipment, electrical enclosures, medical devices, conveyor systems, agricultural machinery, and industrial assemblies where dimensional accuracy is critical. Precision CNC wire forming technology allows manufacturers to produce both simple and complex shapes with high repeatability and tight tolerances. Custom wire forms can be engineered to fit confined spaces, integrate seamlessly with surrounding components, and withstand demanding mechanical and environmental conditions.

Material selection plays a significant role in spring performance, fatigue resistance, corrosion protection, and long term reliability. High carbon spring steels are commonly used for strength and durability in many industrial applications. Stainless steel springs and wire forms are often selected for environments involving moisture, washdowns, or chemical exposure such as food processing, bottling, medical equipment, and outdoor installations. Specialty alloys may be used in applications requiring high temperature resistance, extended cycle life, or enhanced mechanical properties. Working with a domestic spring manufacturer improves material traceability and ensures that raw materials are selected and processed to meet application specific performance requirements.

Precision Manufacturing and Tight Tolerance Control

Precision Manufacturing and Tight Tolerance ControlCustom springs and wire forms made in the USA are produced with a focus on dimensional accuracy, consistent spring rate, and repeatable performance. Tight tolerances are essential for applications where even minor variations in force or geometry can impact equipment function and safety. Modern CNC spring coiling and wire forming equipment enables manufacturers to maintain high precision across both prototype and production runs. Quality control processes including in process inspection, load testing, dimensional verification, and documentation help ensure that each batch of springs meets customer specifications. This level of precision supports OEMs that depend on reliable mechanical components within complex assemblies.

Domestic spring manufacturing offers the advantage of rapid prototyping combined with scalable production support. Prototypes allow engineering teams to validate fit, function, and performance before committing to long term production. Once a design is finalized, USA manufacturers can transition efficiently into production quantities while maintaining consistent quality and process control. This continuity reduces development risk and ensures that spring performance remains predictable throughout the product lifecycle. Close collaboration between OEMs and domestic spring manufacturers improves communication and accelerates problem resolution when design adjustments are required.

Custom springs and wire forms made in the USA are used in applications including electrical switchgear assemblies, turbine systems, medical instruments, industrial automation equipment, packaging machinery, agricultural equipment, firearm components, transportation systems, and infrastructure hardware. Many of these components operate in demanding environments involving high cycle fatigue, vibration, temperature variation, and exposure to moisture or chemicals. Custom engineering and precision manufacturing help ensure long service life and dependable mechanical performance across these diverse applications.

OEMs increasingly choose USA spring manufacturers for consistent quality, responsive service, and dependable lead times. Domestic suppliers offer direct communication with engineering teams, allowing collaborative problem solving and performance optimization. Supply chain stability is another key factor. Domestic production reduces exposure to international shipping delays, geopolitical uncertainty, and fluctuating import costs. For manufacturers focused on long term partnerships and dependable sourcing, American made custom springs and wire forms provide stability, accountability, and performance confidence.

To receive an accurate quote for custom springs or wire forms made in the USA, manufacturers typically provide dimensional specifications such as wire diameter, coil diameter or formed geometry, free length, coil count, material requirements, and any special features required for assembly. Performance requirements including load, torque, travel, or cycle expectations help ensure the part meets functional needs. Photos, drawings, or sample components can speed up the quoting process and reduce interpretation errors. Providing estimated annual usage supports efficient production planning and pricing structure.

If your application requires custom springs and wire forms made in the USA, working with an experienced domestic manufacturer ensures quality, consistency, and responsive technical support. From prototype development through high volume production, precision manufacturing and material expertise make a measurable difference in long term performance and reliability. Ace Wire Spring and Form Co. manufactures custom springs and wire forms to customer specifications with a focus on tight tolerances, dependable performance, and American made quality. With decades of manufacturing experience, our team supports OEMs across multiple industries with reliable spring and wire form solutions.

If you are sourcing custom springs or wire forms for power systems, medical devices, automation assemblies, transportation equipment, or other industrial applications, submit your specifications for a fast and accurate quote. Whether you need prototypes or production quantities, custom springs and wire forms made in the USA can support performance, reliability, and long term manufacturing success.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.