Firearm magazine performance depends on reliable feeding. At the center of that reliability is the magazine spring. Magazine springs are responsible for applying consistent upward force to the follower so rounds feed properly into the chamber across the full range of the magazine, from fully loaded to the last round.

Because magazine springs operate under repeated compression and often reach near solid height, they require careful attention to spring geometry, material selection, and manufacturing consistency. For firearm manufacturers and OEMs, choosing the right magazine spring supplier can help improve function, reduce field failures, and maintain consistent performance across production lots.

Ace Wire Spring and Form Co. manufactures custom magazine springs for firearms to customer specifications, supporting both prototypes and production requirements with a focus on repeatability, tight tolerances, and USA manufacturing.

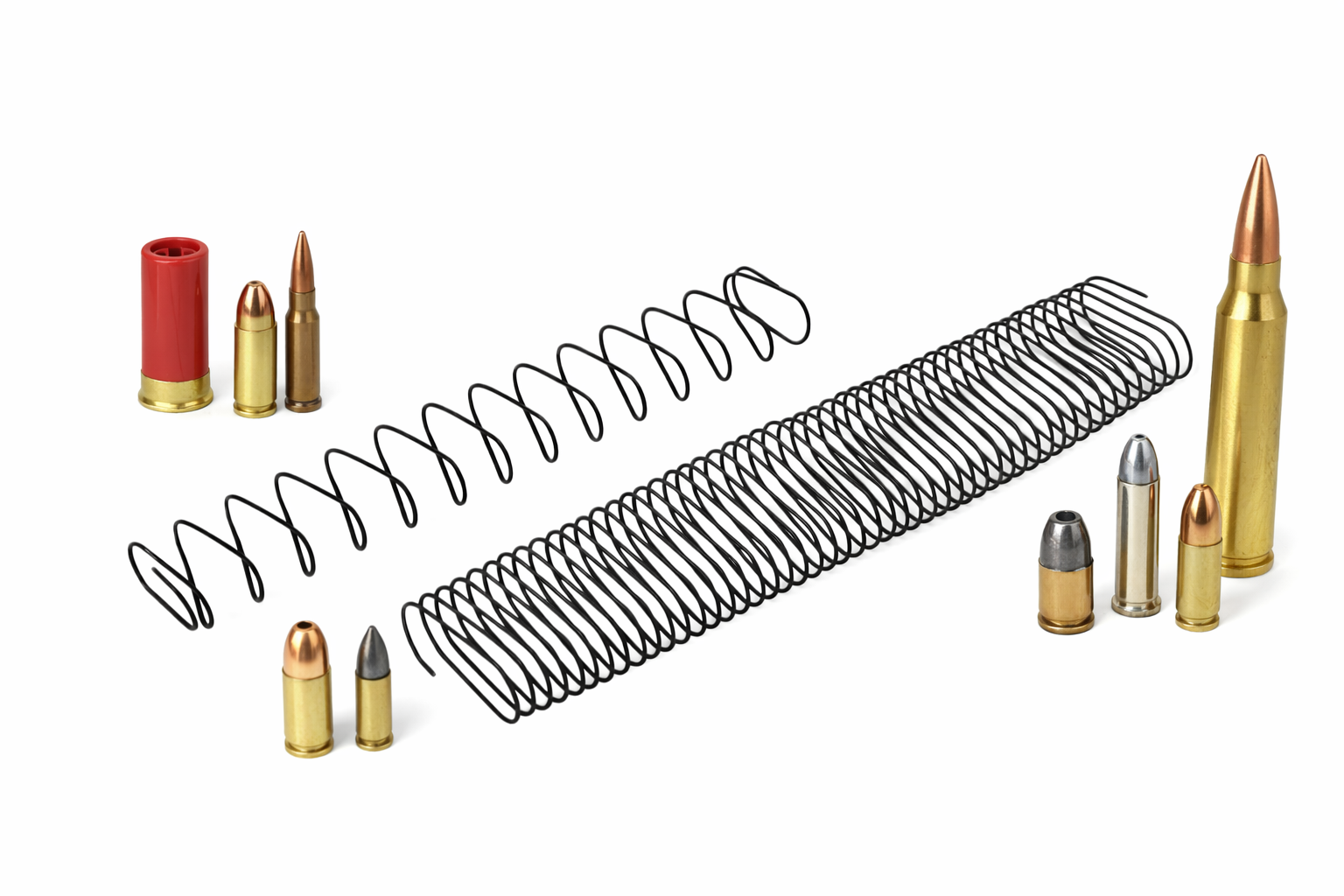

A magazine gun spring is a compression spring that sits inside a firearm magazine. Its job is to push the follower upward so cartridges are presented correctly for feeding. As rounds are loaded into the magazine, the spring compresses. As rounds are fired, the spring expands and maintains upward pressure so the next round is positioned properly.

Magazine springs are commonly formed in oval, rectangular, or other non round shapes depending on magazine geometry. These shapes help maximize usable space inside the magazine body while supporting stable follower travel.

A magazine spring must deliver consistent force throughout the full travel range. If spring force is too low, feeding issues can occur, especially as the magazine approaches the last few rounds. If spring force is too high, it can create unnecessary stress on components or affect loading and cycling behavior depending on the platform.

In production environments, one of the most important requirements is consistency. Even if a magazine spring design works well, variations in wire size, coil geometry, heat treatment, or forming accuracy can cause noticeable differences in performance from spring to spring. That is why quality control and repeatable manufacturing are essential for firearm magazine springs.

Magazine springs are compression springs, but they behave differently than many standard compression spring designs because they often operate at high deflection and must fit within narrow magazine constraints.

Several design factors directly impact magazine spring force, travel, and reliability.

Wire diameter has a major influence on spring force and stress levels. A small change in wire size can significantly change the spring rate and overall load at a given height.

Coil geometry and spring body dimensions also matter. Magazine springs are often not round, which means the spring must be formed precisely to fit the magazine body while maintaining stable compression and controlled movement.

The number of active coils affects spring rate and load. In general, fewer active coils increase spring stiffness while more coils reduce stiffness. Coil count changes also affect solid height, which is critical for magazine spring designs that compress deeply when fully loaded.

Free length impacts available travel. A longer free length can provide more usable deflection and more consistent follower pressure through the firing cycle, but it must still fit the magazine assembly and avoid interference.

Solid height is a critical requirement for many magazine springs. If a magazine spring compresses to solid height during full loading, the spring must be designed so it can reach that condition without overstressing. Springs that are overstressed may take a permanent set, reducing free length and weakening force output over time.

When magazine springs fail in the field, the symptoms often show up as feeding issues, inconsistent follower movement, or reduced spring force. These issues can be caused by several factors.

One common problem is spring set, where the spring loses free length after repeated use or after being compressed beyond safe stress limits. When this happens, the follower may not receive enough upward force to feed the last rounds consistently.

Fatigue failure is another concern, especially for springs operating at high stress across many cycles. Over time, fatigue can lead to cracking or breakage, particularly if the spring design is pushed near material limits or if manufacturing variation increases stress concentration.

Buckling and instability can also occur if the spring is not properly supported within the magazine body. Some designs incorporate features that help stabilize the spring and maintain alignment during compression. If the spring shifts or buckles, it can cause wear, uneven force application, or follower binding.

Corrosion can shorten spring life depending on storage conditions, environmental exposure, and material selection. In applications where corrosion resistance is required, selecting the right material and finish can help maintain long term performance.

Material choice plays a major role in cycle life, performance consistency, and long term reliability. Magazine springs are commonly produced using spring steels selected for strength and fatigue resistance.

The best material depends on the firearm platform, the spring design, and the operating environment. In many cases, manufacturers also consider heat treatment requirements and surface finish to support long cycle life and consistent performance.

For OEMs and firearm manufacturers, it is important to work with a spring supplier that can maintain tight control of material traceability, processing, and repeatability across production runs.

Firearm magazine springs require repeatable performance. Even small changes in spring dimensions can lead to noticeable changes in spring rate, load, and follower pressure.

Maintaining tight tolerances on wire diameter, spring shape, coil spacing, and free length helps ensure consistent feeding performance across large production quantities. This is especially important for manufacturers producing magazines at scale, where repeatability impacts both product quality and customer experience.

Quality focused manufacturing processes and inspection practices help reduce variation and support consistent spring force and long term reliability.

Many firearm manufacturers need prototype magazine springs during early development, followed by production quantities once the design is validated. Prototyping allows for fit checks, function testing, and performance tuning before committing to production.

Once a design is finalized, production spring manufacturing must maintain consistent performance lot to lot. This includes controlled forming, stable material sourcing, and repeatable processing to ensure the magazine spring performs the same way over time.

Ace Wire Spring and Form Co. supports both prototypes and production requirements for custom magazine springs, helping OEMs move from concept to full scale manufacturing with confidence.

To quote custom magazine springs accurately, a spring manufacturer typically needs key dimensional and performance details. This may include wire diameter, spring body shape, free length, coil count, and any special end features required for assembly. If a target load at a specific compressed height is available, that information can help ensure the spring meets functional requirements.

Photos, drawings, or sample springs can also help confirm geometry and reduce quoting delays. For firearm manufacturers focused on production, providing estimated annual usage and packaging requirements can also support faster quoting and better planning.

Firearms manufacturing often requires suppliers that can meet strict quality standards, provide consistent production support, and align with compliance expectations. Working with a USA spring manufacturer helps OEMs maintain supply chain reliability, shorten communication cycles, and support production schedules.

Ace Wire Spring and Form Co. manufactures custom magazine springs and other firearm related springs to customer specifications. With decades of spring manufacturing experience, we support customers who require dependable performance, consistent quality, and responsive quoting support.

If you are sourcing magazine springs for firearms, Ace Wire Spring and Form Co. can assist with prototypes, production runs, and ongoing supply. Share your specifications, drawings, or sample springs and our team will help you move forward with a fast and accurate quote.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.