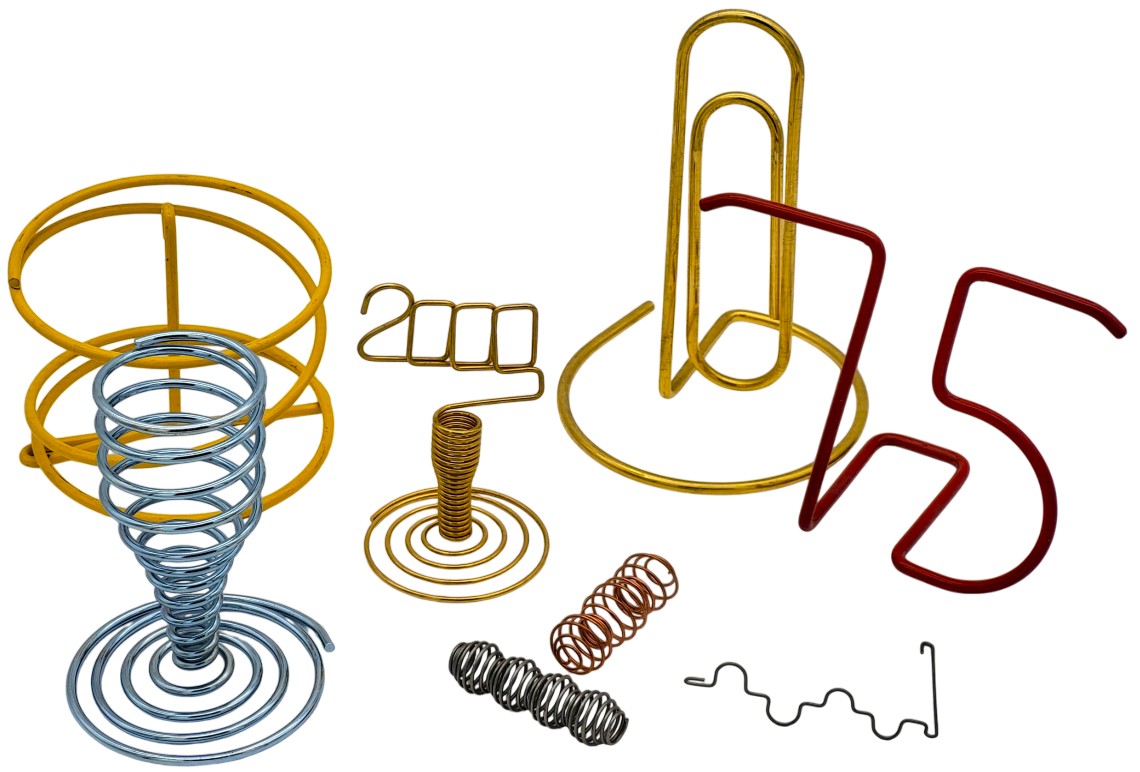

Custom wire forms play an essential role in industries ranging from agriculture to medical, power generation, and conveyor systems. These components may look simple, but their reliability depends heavily on the right design choices. Even minor errors during the design phase can lead to higher production costs, shorter part lifespans, or performance failures.

In this guide, we’ll explore the most common wire form design pitfalls—and, more importantly, how to avoid them. By understanding these issues, engineers can make better material, geometry, and collaboration decisions that ensure high-quality results.

A frequent design error is adding unnecessary complexity to wire forms. It’s natural to think that more bends, loops, or unique features might improve performance, but this often leads to the opposite result.

Why It’s a Problem

Increased cost: Each additional bend or operation requires more tooling and time, raising production costs.

Reduced consistency: Complex forms can be more complicated to reproduce consistently in high volumes, increasing the chance of variability between parts.

Manufacturing inefficiency: Overly intricate shapes may require specialized equipment or multiple steps, extending lead times.

Real-World Example

A farm equipment manufacturer might request a heavy-duty wire retainer with multiple extra bends to ensure it stays in place during operation. While the intention is to improve durability, the added complexity increases production costs and slows down turnaround. In many cases, a simpler U-shaped retainer with the correct material and tension would perform just as well in the field while being more cost-efficient to produce.

How to Avoid It

Prioritize simplicity: Ask, “What is the minimum shape needed to achieve the function?”

Consult manufacturers early: A wire form partner can suggest simpler geometries that reduce operations without compromising performance.

Test prototypes: Prototyping a streamlined design often shows that added complexity isn’t necessary.

Wire forms often experience repetitive motion, tension, or rotational forces. When designers don’t account for stress distribution, weak points can form, leading to cracks or failure.

Why It’s a Problem

Fatigue failures: Sharp bends or abrupt transitions can concentrate stress in one spot, making the wire more prone to breakage.

Reduced lifespan: Even high-quality materials will fail sooner if stress isn’t managed correctly.

Performance issues: A broken spring clip, retainer, or hinge can compromise an entire mechanical assembly.

Real-World Example

In consumer electronics, a wire battery contact that is bent too sharply can work initially but will fail after repeated use, resulting in a product recall or costly redesign.

How to Avoid It

Use proper radii: Incorporating smoother bends helps distribute forces more evenly.

Perform stress analysis: Software simulations or physical testing can reveal hidden weak points.

Prototype and validate: Building prototypes allows engineers to see how a part behaves in real-world conditions before committing to large-scale production.

Material choice is one of the most critical aspects of wire shape design. Selecting the wrong type of wire—or overlooking the finish—can lead to poor performance in the intended environment.

Why It’s a Problem

Corrosion risk: Carbon steel may rust quickly in a humid or marine environment.

Lack of durability: Using a general-purpose material for high-stress applications can cause premature wear.

Missed compliance: In industries like medical or food processing, failing to use appropriate stainless steel or coatings can lead to regulatory issues.

Common Material Choices

Carbon steel: Cost-effective and strong, but not suitable for corrosive environments.

Stainless steel: Ideal for medical, food, and marine use due to corrosion resistance.

Music wire: Provides excellent fatigue resistance and is often used in high-performance spring clips.

Finishing Options to Consider

Plating: Adds a protective or conductive layer.

Passivation: This helps to improve corrosion resistance in stainless steel.

Powder coating: Enhances durability and improves appearance.

Real-World Example

A medical device company may use carbon steel for an IV bag hanger to save on costs. However, repeated sterilization processes would corrode the material quickly. Switching to stainless steel with passivation ensures safety and longevity.

How to Avoid It

Communicate the environment: Share details about exposure to moisture, chemicals, or high heat with the manufacturer.

Request recommendations: An experienced wire form partner can suggest materials and finishes tailored to the application.

Balance cost and performance: Sometimes the slightly more expensive option saves money long-term by avoiding premature failures.

One of the most overlooked design mistakes is delaying manufacturer involvement until the design is finalized. Without manufacturer input, engineers may unknowingly create parts that are expensive or difficult to produce.

Why It’s a Problem

Unnecessary revisions: A design that isn’t manufacturable may require costly rework.

Missed efficiencies: Opportunities to simplify geometry, reduce secondary operations, or shorten lead times may be lost.

Longer production cycles: Redesign delays push projects back, affecting overall schedules.

Real-World Example

In conveyor system design, engineers often require specially shaped wire components to guide, hold, clamp, or connect items moving along the line. A designer might specify a complex shape made from a specialty alloy, believing it will improve performance. However, when shared with the manufacturer, the alloy may not be readily available, and the tolerances may be too strict for efficient production.

A simpler design using standard stainless steel or carbon steel could achieve the same function while reducing cost, lead time, and production challenges.

How to Avoid It

Collaborate early: Involve manufacturers during the initial concept stage.

Leverage DFM principles: Design for manufacturability by simplifying shapes, reducing steps, and selecting available materials.

Ask for prototyping: Quick samples can confirm feasibility before moving into full production.

Putting It All Together: Smarter Wire Form Design

By recognizing these wire form design pitfalls—overengineering, underestimating stress points, choosing the wrong material, and failing to collaborate—engineers can improve performance and cost efficiency.

At Ace Wire Spring & Form Co., Inc., we emphasize communication and collaboration. When customers share details such as load requirements, space constraints, and environmental conditions, our engineering team can recommend the best materials, finishes, and designs. Prototyping and validation ensure that every part meets both functional and manufacturability requirements before full-scale production begins.

Custom wire forms may look simple, but thoughtful design is what ensures they perform reliably in demanding applications. By avoiding common errors and working closely with an experienced manufacturer, engineers can reduce risks, control costs, and achieve better long-term results.

With over 85 years of experience in custom wire forms and springs, Ace Wire Spring & Form Co., Inc. provides the technical expertise and USA-based manufacturing needed to bring your project from prototype to production.

Ready to start your next project? Contact us today to request a quote, discuss your design, or learn more about designing wire forms that meet your performance goals.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.