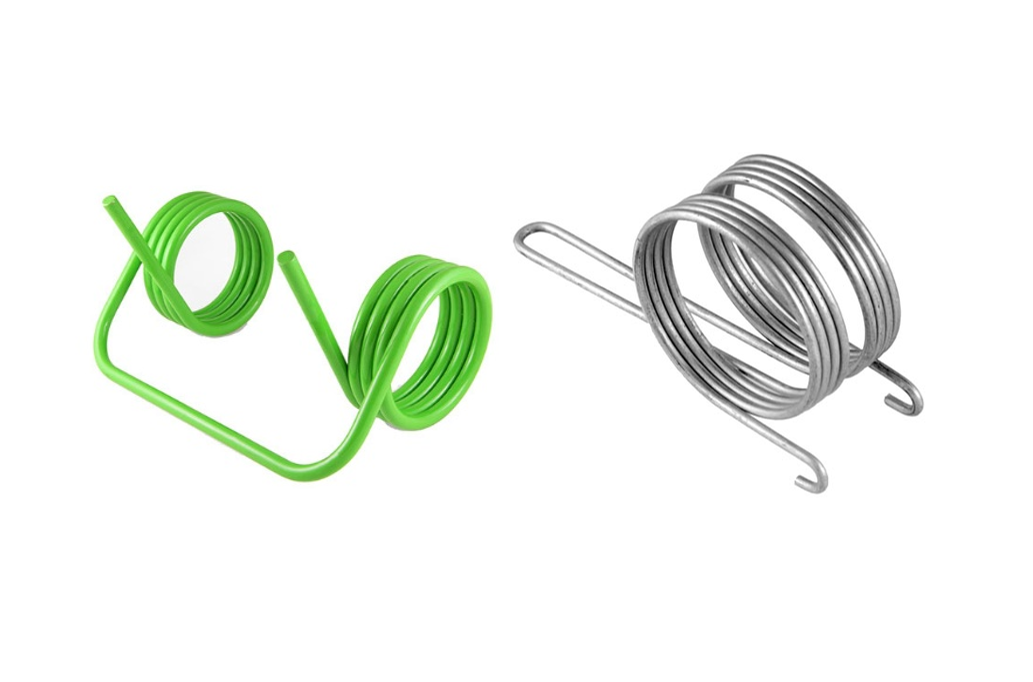

Double torsion springs feature two connected coils—one right-hand and one left-hand—working in parallel to deliver balanced, high-torque performance. Designed to minimize friction and maximize rotational force, these springs are ideal for precision applications that require smooth and controlled movement.

Explore our double torsion spring capabilities by visiting our Other Spring Types page.

Ace Wire Spring & Form Co., Inc. specializes in large-diameter torsion springs, engineered for high-torque applications in agriculture, power generation, trailers, and liftgate systems. Our state-of-the-art manufacturing equipment allows us to produce heavy-duty torsion springs with exceptional durability and performance, even in demanding environments. With our advanced machinery and expert engineering team, we can customize torsion springs to meet your exact specifications, ensuring reliability and longevity for your application.

Ace Wire Spring & Form Co., Inc. specializes in manufacturing high-performance torsion springs for trailers and liftgates, engineered for durability and reliability in heavy-duty applications. Our trailer torsion springs are designed for ramp and gate lift assist, providing the necessary torque to ensure smooth, controlled operation when raising and lowering trailer gates. We also produce large-diameter torsion springs for heavy-duty equipment trailers, utility trailers, and enclosed cargo trailers, ensuring safe and efficient loading and unloading.

In addition to trailer applications, we manufacture torsion springs for liftgates, commonly used in work trucks, delivery vehicles, and loading dock lift systems. These springs play a critical role in counterbalancing liftgate mechanisms, enabling seamless lifting and lowering of heavy cargo. Whether in logistics, freight transport, or material handling, our liftgate springs are built to withstand repeated use while maintaining optimal performance.

As a certified member of the National Association of Trailer Manufacturers (NATM), Ace Wire Spring & Form Co., Inc. adheres to the highest industry standards. Our team of expert engineers works closely with customers to develop custom torsion springs tailored to specific load requirements, ensuring maximum efficiency and longevity. From initial design and prototyping to full-scale production, we are committed to delivering precision-engineered torsion springs that exceed industry expectations.

Take a moment to explore the variety of additional services Ace Wire Spring & Form Co. Inc., can perform on any type of spring or wire form to enhance performance and durability. From heat treatment, deburring, and painting to many more offerings, our secondary services are designed to meet your specific needs. Please include the secondary services you would like to add in the comment section of your request for quote, and our engineers will return an accurate and timely quotation with the added services. Visit our Secondary Services Page to learn more.

To review springs and wire form finishes such as e-coating, zinc plating, passivation, and many more, visit Wire Size and Material Range Page.

At Ace Wire Spring & Form Co., we provide flexible and reliable solutions to meet your manufacturing needs. Our expertise ensures precision, quality, and efficiency from prototype to production. For more details on these value-added services, visit our Custom vs. Stock Springs Page.

After determining the force of torque required a designer usually estimates a suitable space or size limitations. The space should be considered approximate until the wire size and number of coils have been determined. The wire size depends solely on the torque.

When ordering a torsion springs or double torsion springs spring remember to give the following information as completely as possible:

This video shows how Torsion Springs are manufactured.

For more information about torsion springs or to talk to one of our experts call 1-800-828-3353.

ACE specializes in custom precision springs and wire forms, offering a distinct advantage by utilizing the most advanced spring design software. ACE validates each existing and new design, notifying the customer with our recommendations.

Copyright © Ace WIre Spring & Form Company, Inc. All Rights Reserved. Pittsburgh Website Design by Higher Images.