Compression Springs

Ace Wire Spring & Form designs and manufactures custom compression springs to the exact requirements of our customers’ needs. Compression springs are open coiled helical springs that resist a compressive force applied axially. They may be tapered, conical, cylindrical, convex or concave in shape. The changing of the ends, direction of the helix, material and finish allows the springs to meet a variety of specially designed needs.

Need a quote for compression springs? Click here to get one today.

What are Compression Springs?

A type of wire spring used in everything from appliances to motorized equipment, motors, and more. Compression is compressed by a load acting upon them or their ends are compressed, the design of the wire tries to return it back to the original shape thus pushing the load back. They are designed and used to resist applied compressive forces or to store energy in the push mode. Typically, they are cylindrical helical made out round wire. However, they can be made conical, oval, barrel or virtually any other shape. The wire can also be round, square or rectangular. This is the most common configuration and are found in many applications such as automotive, aerospace and consumer goods.

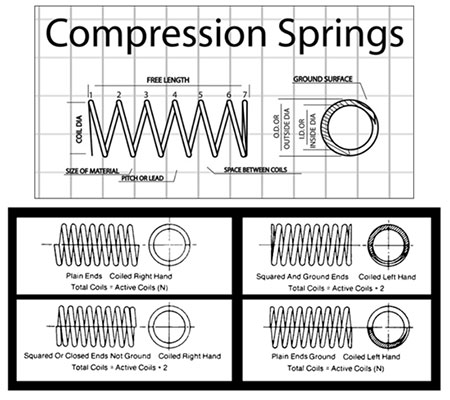

One can control the actions of compression springs by how they are designed. The diameter of the coil, the number of coils, the style of the ends even the length and diameter and shape of the wire can all make different designs. This is why it is so important to have all the right dimensions when ordering so its performance will meet the needs of the application.

Ace has been manufacturing and designing custom springs since 1939 and has helped thousands of companies fill a need for the job but also offer a variety of design and manufacturing services. We are large enough to provide capacity and repeatability yet small enough to still offer custom design and production runs for special requirements.

Whether you need help in specifying or designing, or just looking for an American manufacturer, Ace would be happy to demonstrate our capabilities and quality for you.

Types & Stress Levels

Compression Spring Types:

Compression Springs are open-coil helical springs that offers resistance to a compressive force applied axially. Helical compression springs are used to resist applied compression forces or to store energy in a push mode. Compression springs have the most common configuration and are most commonly used in automotive, aerospace and consumer applications. Most compression springs are a straight cylindrical spring made of round wire. Ace Wire Spring & Form, a manufacturer of compression springs produces a variety of compression types, shapes, and specific specifications. Click here for compression springs specifications.

Compression springs from a manufacturer come in a variety of types including: Conical Compression, Barrel, Hourglass and Cylindrical shapes and may have various spacing or no spacing at all between coils.

Wire Selection: rectangular, round, square or special-section. Round being the most adaptable.

Compression Spring Mandatory Specification: the functional design characteristics.

Compression Spring Secondary Specification: the secondary characteristics, which is useful for reference and should be considered advisory data.

Dimensional Limits: governed by the space allotted with regard to allowable solid height and outside and inside diameters.

Spring Stress Level: determined by the dimensional limits together with the load and deflection requirements. Our compression springs are stress-relieved to remove residual bending stresses produced by the coiling operation.

Compression Spring Stress Levels:

A compression spring that can be compressed solid without permanent set, so that an extra operation for removing set is not needed. These springs are designed with torsional stress levels when compressed solid that do not exceed about 40 percent of the minimum tensile strength of the material.

A compression spring which can be compressed solid without further permanent set after set has initially be removed. These may be pre-set by the spring manufacturer as an added operation, or they may be pre-set later by the user prior to or during the assembly operation. These are springs designed with torsional stress levels when compressed solid that do not exceed 60 percent of the minimum tensile strength of the material.

Springs which cannot be compressed solid without some further permanent set taking place because set cannot be completely removed in advanced. These springs involve torsional stress levels which exceed 60 percent of the minimum tensile strength of the material. The spring manufacturer will usually advise the user of the maximum allowable spring deflection without set whenever springs are specified in this category.

Remember: It is extremely important to consider carefully the space allotted to insure that the compression spring will function properly to begin with, thereby avoiding costly design changes.

Design & Specifications

How to Determine Rate for Compression Springs

For Compression Springs - Rate which is the change in load per unit deflection, may be determined by the following procedure:

1. Deflect spring to approximately 20 percent of available deflection and measure load (P1) and spring length (L1).

2. Deflect spring to approximately 80 percent of available deflection and measure load (P2) and spring length (L2). Be certain that no coils (other than closed ends) are touching L2.

3. Calculate rate (R) lb./in. (N/mm)

R = (P2 - P1) / (L1 - L2)

Solid Height of Compression Springs

The solid height of compression springs is defined as the length of the spring when under sufficient load to bring all coils into contact with the adjacent coils and additional load causes not further deflection. Solid height should be specified by the user as a maximum, with the actual number of coils in the spring to be determined by the spring manufacturer.

As square or rectangular wire is coiled, the wire cross-section deforms slightly into a keystone or trapezoidal shape, which increased the solid height considerably. The dimensional change is a function of the spring index and the thickness of the material.

Ends of Compression Springs

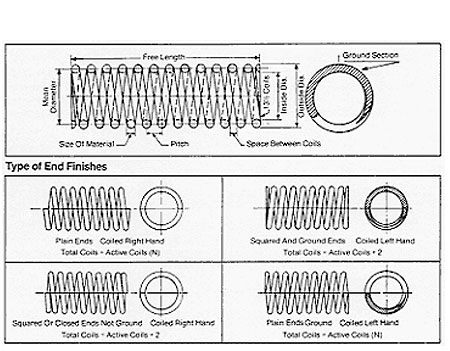

There are four basic types of compression springs ends as shown above.

The particular type of ends specified affect the pitch, solid height, number of active and total coils, free length and seating characteristics of the spring.

Videos

Ace Wire Springs is proud to share a video showing how compression springs are manufactured.

Information Needed For Ordering Compression Springs:

Free Length, Maximum, Minimum. Controlling Diameter, Outside Diameter Maximum. Inside Diameter Minimum. Pitch Diameter. Works Inside (Dia. Hole). Works Over (Dia. Shaft). Number of Coils Wire Size. Decimal size if possible. Material, Kind and Grade. Loads at deflected positions. Style of Ends, (see illustrations). Right- or Left-Hand Wound. Finish. Plain unless otherwise specified. Maximum Solid Length. Frequency of Compression.