Custom Spring Design Specifications & Ordering Hints

Overview

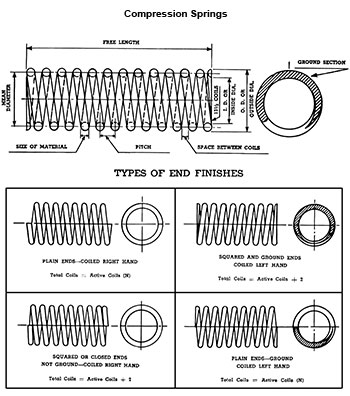

Specifications for Compression Springs

Specifications for Compression Springs

In Ordering Give the Following Information as Completely as Possible:

-

Free Length, Maximum, Minimum.

-

Controlling Diameter, Outside Diameter Maximum.

Inside Diameter Minimum. Pitch Diameter. Works Inside

(Dia. Hole). Works Over (Dia. Shaft). -

Number of Coils

-

Wire Size. Decimal size if possible.

-

Material, Kind and Grade.

-

Loads at deflected positions.

-

Style of Ends, (see illustrations).

-

Right or Left Hand Wound.

-

Finish. Plain unless otherwise specified.

-

Maximum Solid Length.

-

Frequency of Compression.

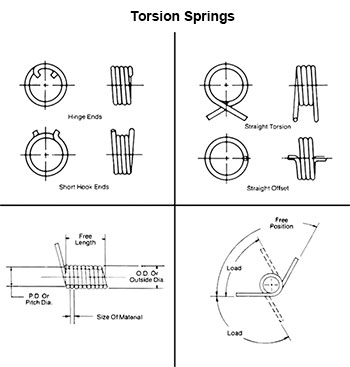

Specifications for Torsion Springs

Specifications for Torsion Springs

In Ordering Give the Following Information as Completely as Possible:

-

Inside or Outside Diameter.

-

If spring works on a rod, give size of same, as spring must not bind when wound up to its limit of travel.

-

Free length and number of coils. If spring cannot increase in length as wound up, allow sufficient space between coils.

-

Right or Left Hand Wound.

-

Wire Size. Decimal size if possible.

-

Material, Kind and Grade.

-

Style of Ends, (see illustrations).

-

Number of turns deflection to hold given load and radius of loaded arm. This length may be the length of the arm, or the arm may be attached to a movable machine member, in which case the length to point of application of load is given.

-

Finish, Plain unless otherwise specified.

Specifications for Extension Springs

In Ordering Give the Following Information as Completely as Possible:

-

Length, Maximum, Minimum, (Overall, Over coil, Inside Hooks).

-

Controlling Diameter: Outside Diameter Maximum. Inside Diameter Minimum.

-

Wire Size. Decimal size if Possible.

-

Material, Kind and Grade.

-

Number of Coils.

-

Style of Ends (see illustrations)

-

Right or Left Hand Wound.

-

Finish (Plain unless otherwise specified).

-

Load Required, Length Inside-Hooks (Length of Coil if wire size not specified).

-

Maximum Extended Length (Overall, Over coil, Inside Hooks).

-

Deflection or Distance of Travel.

-

Frequency of Extension.

-

Is Position of Ends Important? (Make the ends of springs bear a definite relation to each other usually adds to the cost of manufacture.)

Note: Extension springs made from tempered or hand-drawn wires can be and usually are wound with initial tension. Such tension may average 20% of the total safe stress of the springs, but will not increase the elastic limit.

Coil Direction

To determine coil direction hold with Axis of spring on Horizontal Plane. Angle of coil from top to bottom determines direction.